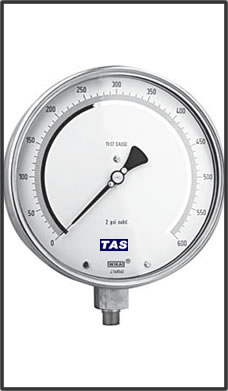

High Precision Industrial Gauges

Time Access Solutions provides the most reliable Process Gauges, Process Pressure Gauges, Duragauge® Pressure Gauges, Stainless Pressure Gauges, Test Gauges, Commercial Gauges, Digital Pressure Gauges, Diaphragm Seals, Temperature gauges and switches.

|

|

High Precision Gauges

Type 312.20

- Mirrored Dial

- Stainless Steel Case & Ring

- +0.25% of Span Accuracy

Extremely sensitive and highly accurate, Type 312.20 test gauges are excellent for instrument shops, gauge repair and calibration shops, testing laboratories and other applications demanding high precision and consistent results. 312.20 test gauges feature adjustable knife-edge pointers and mirror bands on the dial to assure precise readings and to eliminate parallax error.

Standard Features

Size: 6" (160 mm)

Case: Stainless steel

Bayonet Ring: Stainless steel

Wetted Parts: Copper alloy

Movement: Brass with nickel-silver pinion gears and shaft

Window: Laminated safety glass

Dial: White aluminum with mirrored band

Pointer: Black aluminum, knife-edge

Accuracy: + 0.25% of span ASME B40.100 Grade 3A

|

| |

|

|

High Precision Gauges

Type 332.30

- Solid Front, Blow-out Back

- Mirrored Dial

- +0.25% of Span Accuracy

Type 332.30 test gauges feature a solid-front, blow-out back safety case design, adjustable knife-edge pointers, and mirror bands on the dial to assure precise readings and to eliminate parallax error. Extremely sensitive and highly accurate, Type 332.30 test gauges are excellent for instrument shops, gauge repair and calibration shops, testing laboratories and other applications demanding high precision and consistent results.

Standard Features

Size: 6" (160 mm)

Case: Stainless steel

Bayonet Ring: Stainless steel

Wetted Parts: 316 SS - 332.30

Movement: Stainless steel

Window: Laminated safety glass

Dial: White aluminum with mirrored band

Pointer: Black aluminum, knife-edge

Accuracy: + 0.25% of span ASME B40.100 Grade 3A

|

| |

|

|

High Precision Gauges

Type 332.34

- Rugged Thermoplastic Case

- Stainless Steel Case Wetted Parts

- +0.25% of Span Accuracy

The Type 332.34 is an industrial type gauge suitable for corrosive environments where the fluid medium does not clog connection or corrode wetted part material. Solid front, blow-out back case design meets safety requirements of ASME B40.100.

Standard Features

Size: 4½" (115 mm)

Accuracy: + 0.25% of span (ASME B40.100 Grade 3A)

Ranges: 0/30" Hg Vac through 0/600 PSI

0.25% of span (ASME B40.100 Grade 3A)

Ranges: 0/2000 PSI through 0/20,000 PSI

0.25% of span (ASME B40.100 Grade 3A)

Note: Not available in ranges 600>2000 PSI

Ranges: (All ranges not stocked) Vacuum 30" Hg; Pressure from 15 PSI to 20,000

PSI (all ranges not available) or other equivalent units of pressure or vacuum

Working Range: Steady: 3/4 of full scale value; Fluctuating: 2/3 of full scale value;

Short time: full scale value

Operating Temperature: Ambient: -40°F to 140°F (-40°C to 60°C);

Media: max. 212°F (+100°C)

|

| |

|

|

High Precision Gauges

Type 332.54

- Mirrored Dial

- Stainless Steel Case Wetted Parts

- +0.25% of Span Accuracy

Type 332.54 inspector's test gauges are convenient for field calibrations. They have an accuracy of ±0.25% which meets ASME B40.100 Grade 3A. The mirrored band on the dial and the knife-edge pointer make it easy to take accurate readings from the gauge. Type 332.54 test gauges are supplied standard with a nylon, zippered carrying pouch.

Standard Features

Size: 4" (100 mm)

Case: 304 SS

Bayonet Ring: Polished SS

Wetted Parts: 316 SS

Window: Safety glass

Dial: White aluminum with mirrored band

Pointer: Black, adjustable knife edge

O-ring: EPDM

Accuracy: ± 0.25% of span (ASME B40.100 Grade 3A); Ranges 0/30" Hg Vac through 0/600 PSI; 0.25% of span (ASME B40.100 Grade 3A) ) 0/2000 PSI through 0/20,000 PSI

|

| |

|

|

High Precision Gauges

Type 342.11

- Mirrored Dial

- Stainless Steel Case Wetted Parts

- +0.25% of Span Accuracy

Type 332.54 inspector's test gauges are convenient for field calibrations. They have an accuracy of ±0.25% which meets ASME B40.100 Grade 3A. The mirrored band on the dial and the knife-edge pointer make it easy to take accurate readings from the gauge. Type 332.54 test gauges are supplied standard with a nylon, zippered carrying pouch.

Standard Features

Size: 4" (100 mm)

Case: 304 SS

Bayonet Ring: Polished SS

Wetted Parts: 316 SS

Window: Safety glass

Dial: White aluminum with mirrored band

Pointer: Black, adjustable knife edge

O-ring: EPDM

Accuracy: ± 0.25% of span (ASME B40.100 Grade 3A); Ranges 0/30" Hg Vac through 0/600 PSI; 0.25% of span (ASME B40.100 Grade 3A) ) 0/2000 PSI through 0/20,000 PSI

|

|